Igwe ịgbado ọkụ laser ejiri aka

Akụkụ ọdịnaya nkọwa dị mkpirikpi

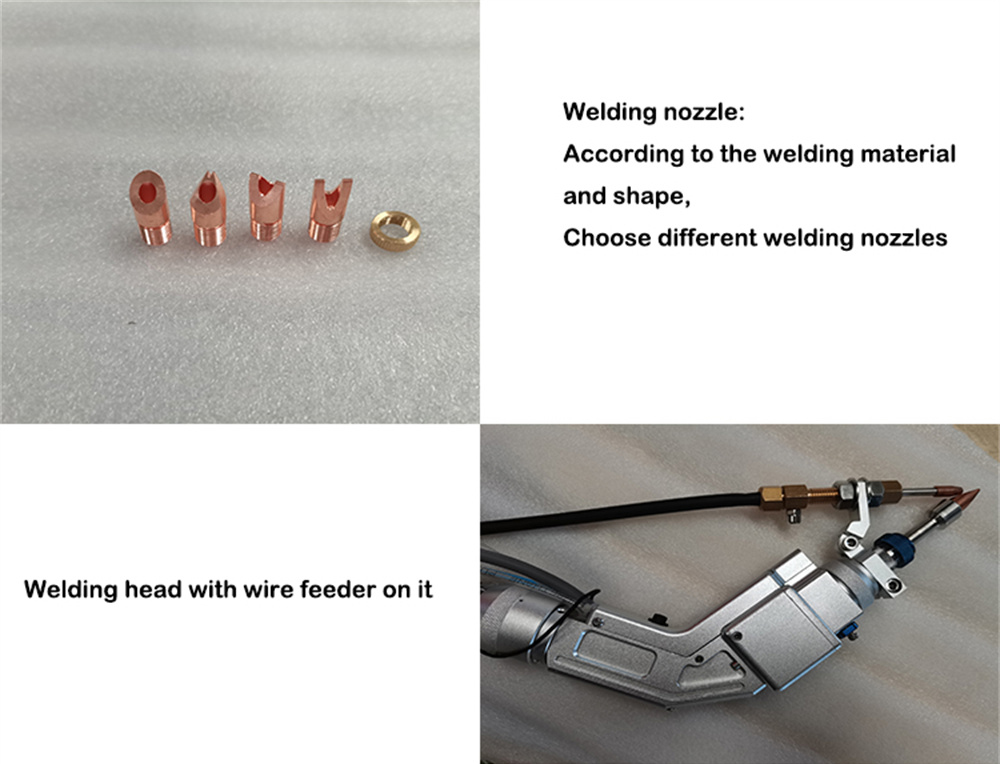

- Enwere ụdị ịgbado ọkụ 6 na ọtụtụ nozzles ịgbado ọkụ iji gboo mkpa ịgbado ọkụ dị iche iche;ọ nwere ọrụ ihe mmetụta nchekwa, nke na-ewepụta laser mgbe ọ metụrụ metal ahụ aka ma na-emechi ọkụ na-akpaghị aka mgbe ewepụrụ ya.

- Ejiri igwe na-enye igwe na-enye akpaaka, nke nwere ike ịhazigharị paramita ngwa ngwa ma nye ọtụtụ nhọrọ maka

ndị ahịa.

- Enwere ụdị ịgbado ọkụ 6 na ọtụtụ nozzles ịgbado ọkụ iji gboo mkpa ịgbado ọkụ dị iche iche;ọ nwere ọrụ ihe mmetụta nchekwa, nke na-ewepụta laser mgbe ọ metụrụ metal ahụ aka ma na-emechi ọkụ na-akpaghị aka mgbe ewepụrụ ya.

- Igwe ọkụ abụọ na njikwa abụọ, sekit mmiri na-ekesa, nwere ike ajụkwa oghere dị n'ime pipeline nke isi ịgbado ọkụ, ka ọ na-eme ka laser dị jụụ.

Ngosipụta ngwaahịa

Nka nka

| Ọnọdụ | Ọhụrụ | Ngwa ndị isi | Isi iyi Laser |

| Ojiji | Weld metal | Oke.Ike mmepụta | 2000W |

| Ngwa ọdabara | Ọla | Cnc ma ọ bụ ọ bụghị | Ee |

| Ọnọdụ jụrụ oyi | Mmiri jụrụ oyi | Ngwa njikwa | Ruida/Qilin |

| Obosara Pulse | 50-30000Hz | Ike Laser | 1000w/ 1500w/ 2000w |

| Arọ (Kg) | 300 n'arọ | Asambodo | Ce, ISO9001 |

| Ngwa ndị isi | Isi iyi Laser Fiber, Fiber, Handle Laser Weld Head | Isi ihe ire ere | Oke-nkenke |

| Ọrụ | Metal Part Laser Welding | Ogologo eriri | ≥10m |

| Ụlọ ọrụ ọdabara | Ụlọ oriri na ọṅụṅụ, Ụlọ ahịa uwe, Ụlọ ahịa ihe eji arụ ụlọ | Ngwa ndị isi | Ntinye Laser |

| Ụdị Ọrụ | Akụdara | Mgbe ọrụ akwụkwọ ikike gasịrị | Nkwado n'ịntanetị |

| Dayameta Focal Spot | 50μm | Ogologo ogologo | 1080 ± 3nm |

| Nnyocha ọpụpụ vidiyo | Enyere ya | Akwadoro usoro eserese | Ai, Plt, Dxf, Dwg, Dxp |

| Ebe Mmalite | Jinan, Shandong Province | Oge ikike | Afọ 3 |

Isi akụkụ maka igwe

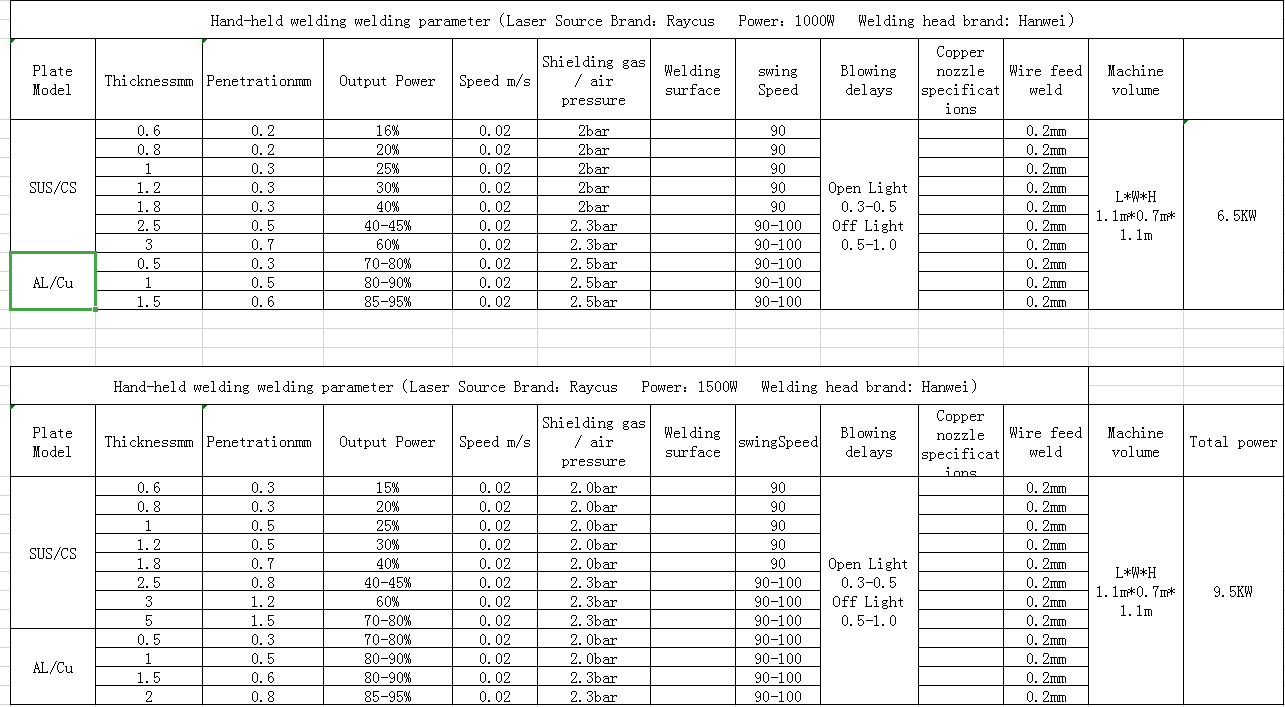

Oke ịgbado ọkụ maka igwe ịgbado ọkụ laser

Nhazi

| Ike Laser | 1000w | 1500W | 2000W | ||||||

| Ihe ịgbado ọkụ | Igwe anaghị agba nchara | Carbon ígwè | Aluminom | Igwe anaghị agba nchara | Carbon ígwè | Aluminom | Igwe anaghị agba nchara | Carbon ígwè | Aluminom |

| Ọkpụrụkpụ Welding (Mm) | 2 | 2 | 1 | 3 | 3 | 2 | 4 | 4 | 3 |

| Ọkpụrụkpụ Welding (inch) |

|

|

|

|

|

|

|

|

|

| Waya ịgbado ọkụ na-agbanwe agbanwe | Welding waya dayameta 0.8-1.6mm | ||||||||

| Weld Seam chọrọ | Ịgbado ọkụ nke Waya ≤1Mm Welding Swinging ≤15% nke ọkpụrụkpụ efere≤0.3Mm | ||||||||

| Ibu igwe | 220kg | 220kg | 300kg | ||||||

| Nha igwe(Mm) | 954X715X1080 | 954X715X1080 | 1155X715X1160 | ||||||

| Ogologo Ahịrị Welding Gun | 10m (The Wire Feed Tube of Wire Feeder bụ 3 Mita ogologo) | ||||||||

| Welding egbe arọ | Ụdị enyo na-ama jijiji (Qi Lin): 0.9Kg | ||||||||

| Ike igwe | 7kw | 9kw | 12Kw | ||||||

| Asụsụ akwadoro | Ọkọlọtọ: Chinese, Bekee, Korean, Vietnamese, Russian Enwere ike ịhazi Japanese na Spanish | ||||||||

| Voltaji na Frequency | Ọkọlọtọ: 380V/50Hz voltaji ndị ọzọ yana ugboro bụ nhọrọ | ||||||||

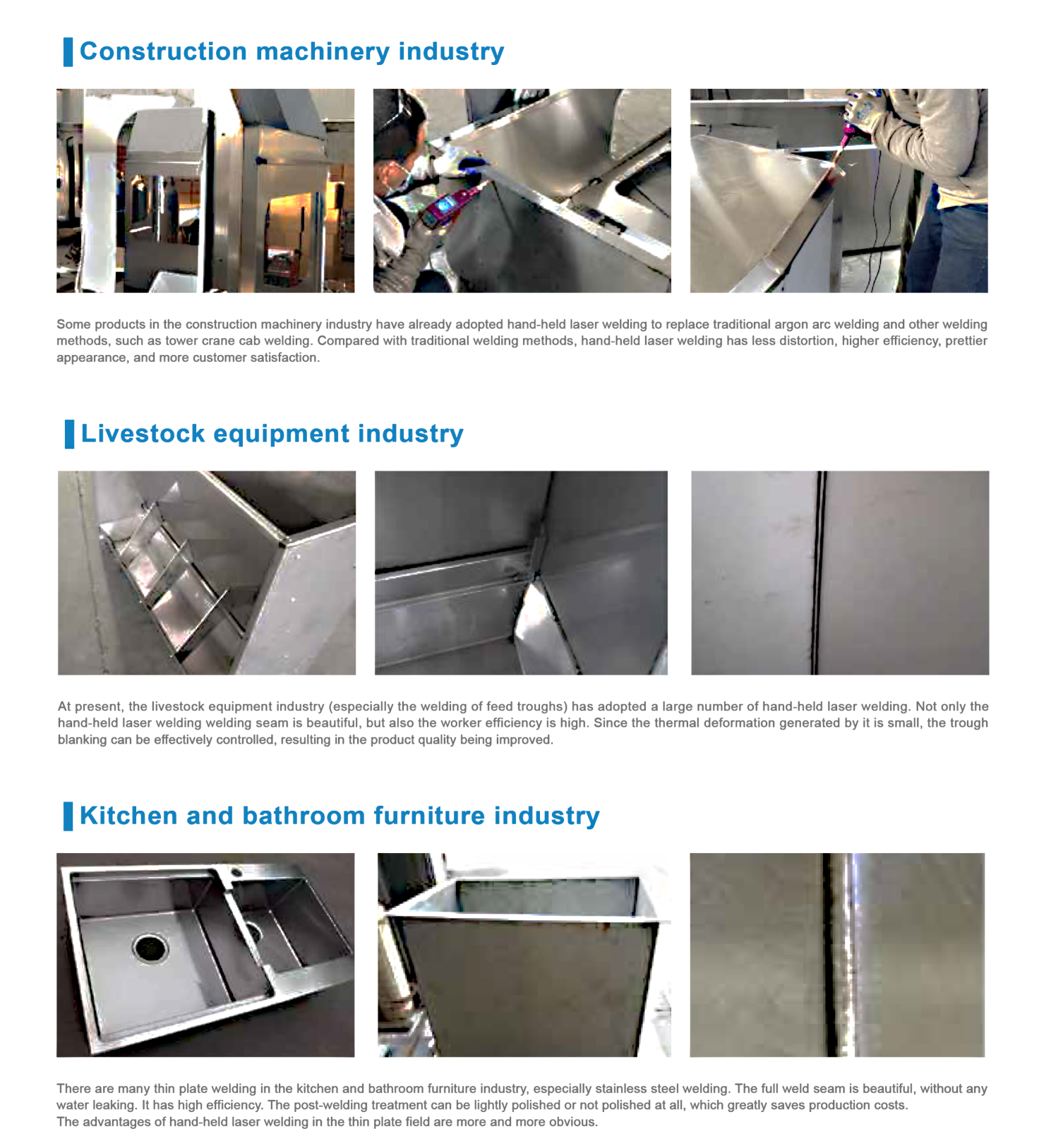

Ụlọ ọrụ ngwa

A na-eji igwe ịgbado ọkụ laser eme ihe n'ọtụtụ ebe na ụlọ ọrụ ịsa ahụ: ịgbado ọkụ nke nkwonkwo ọkpọ mmiri, ibelata nkwonkwo, tees, valves, na ịsa ahụ.Ụlọ ọrụ iko: nkenke ịgbado ọkụ nke igwe anaghị agba nchara, titanium alloy na ihe ndị ọzọ na ikechi ọnọdụ, mpụta etiti na ndị ọzọ na ọnọdụ nke iko.Ụlọ ọrụ akụrụngwa: impeller, kettle, handle, etc., ịgbado ọkụ nke mgbagwoju stamping akụkụ na nkedo akụkụ.A na-eji igwe ịgbado ọkụ laser eme ihe n'ọtụtụ ebe na ụlọ ọrụ akpaaka: gaskets engine cylinder, ịgbado ọkụ hydraulic tappet, ịgbado ọkụ ọkụ, ịgbado ọkụ nzacha, wdg.

Uru nke igwe ịgbado ọkụ laser

1. Wide ịgbado ọkụ nso: A na-eji isi ịgbado ọkụ nke 5m-10m nke mbụ, nke na-emeri njedebe nke oghere workbench ma nwee ike iji ya mee ihe maka ịgbado ọkụ n'èzí na ịgbado ọkụ dị anya;

2. Dị mma ma na-agbanwe agbanwe iji: A na-eji eriri laser na-eme ka ọ dị mma na-eme ka ọ dị mma, na-enwe ike ịhazi ya n'oge ọ bụla, na-enweghị mkpa maka ọdụ ụgbọ oloko, free na mgbanwe, na adabara dị iche iche. ọnọdụ gburugburu ọrụ.

3. Ụzọ ịgbado ọkụ dị iche iche: ịgbado ọkụ n'akụkụ ọ bụla nwere ike imezu: ịgbado ọkụ nkedo, ịgbado ọkụ, ịgbado ọkụ kwụ ọtọ, ịgbado ọkụ fillet dị larịị, ịgbado ọkụ n'ime fillet, ịgbado ọkụ n'èzí, wdg.Enwere ike nweta ịgbado ọkụ n'akụkụ ọ bụla.Ke adianade do, o nwekwara ike mezue ọnwụ, ịgbado ọkụ na ọnwụ nwere ike Switched kpam kpam, dị nnọọ ịgbanwe ịgbado ọkụ ọla kọpa nozulu na ọnwụ ọla kọpa nozulu, nke dị nnọọ adaba.

4. Mmetụta ịgbado ọkụ dị mma: ịgbado ọkụ laser ejiri aka bụ ịgbado ọkụ na-ekpo ọkụ.E jiri ya tụnyere ịgbado ọkụ ọdịnala, ịgbado ọkụ laser nwere njupụta ume dị elu ma nwee ike nweta mmetụta ịgbado ọkụ ka mma.Chọpụta nsogbu, nnukwu ịgbado ọkụ omimi, zuru ezu agbaze, guzosie ike na a pụrụ ịdabere na, na weld ike erute ma ọ bụ ọbụna gafere isi metal n'onwe ya, nke na-enweghị ike na-ekwe nkwa site nkịtị ịgbado ọkụ igwe.

5. Ọ dịghị mkpa ka a na-ehicha ihe nkedo ịgbado ọkụ: Mgbe ịgbado ọkụ ọdịnala gasịrị, ọ dị mkpa ka a na-ehicha ebe a na-agbado ọkụ iji hụ na ọ dị ire ọ bụghị nke siri ike.Igwe ịgbado ọkụ laser ejiri aka na-egosipụta naanị uru ndị ọzọ na nsonaazụ nhazi: ịgbado ọkụ na-aga n'ihu, na-adị ire ụtọ na-enweghị akpịrịkpa azụ, mara mma na-enweghị ọnya, yana usoro ịkụcha ihe na-esote.

6. Enweghị ihe ọ bụla maka ịgbado ọkụ: N'ọtụtụ echiche ndị mmadụ, ọrụ ịgbado ọkụ bụ "enyo n'aka ekpe na waya ịgbado ọkụ n'aka nri".Otú ọ dị, site na igwe ịgbado ọkụ laser ejiri aka, a na-eme ka ọkpụkpụ ahụ dị mfe, na-ebelata ọnụ ahịa ihe onwunwe na mmepụta na nhazi.

7. Na otutu nchekwa mkpu, na ịgbado ọkụ n'ọnụ bụ nanị irè mgbe mgba ọkụ na-emetụ mgbe ọ na-emetụ na metal, na ìhè na-akpaghị aka ekpochi mgbe workpiece wepụrụ, na aka mgba ọkụ nwere a ahu okpomọkụ sensọ.Nchekwa dị elu, na-ahụ maka nchekwa nke ndị na-arụ ọrụ n'oge ọrụ.

8. Chekwaa ụgwọ ọrụ: Tụnyere arc ịgbado ọkụ, ọnụ ahịa nhazi nwere ike belata ihe dịka 30%.Ọrụ ahụ dị mfe ma dị mfe ịmụta na ngwa ngwa ịmụta, na ọnụ ụzọ teknụzụ nke onye ọrụ adịghị elu.Enwere ike were ndị ọrụ nkịtị were obere oge ọzụzụ, ma nwee ike nweta nsonaazụ ịgbado ọkụ dị elu ngwa ngwa.